| 13 Seconds next ... How to build a Mustang-stomping Chrysler

Turbo 4 ... BY TOM HAND. |

Most Mopar fans are convinced that performance stopped in 1971 with the

death of the Hemi. I'm not one of those, but I admit the new breed of cars

from Chrysler has to be attacked from a slightly different but somewhat

similar angle. I've grown up with a couple of 340 4-speed cars, and I've

found there are a lot of little tricks that add up to a big performance

increase, even on the new front-wheel-drive cars. Chrysler has stayed with

the FWD platform since the first K-cars in 1981, and it didn't appear that

they were going back to the rear-wheel-drive high performance cars of the

'60s. I've always enjoyed the sleeper cars, such as 340 Darts and Dusters,

so I chose as my '80s sleeper a 1984 Dodge 600 with a turbocharged 2.2

liter (135 cubic inch) engine and an automatic transmission. A quick look

at the Dodge reveals air conditioning, tilt wheel, six-speaker AM/FM cassette

and a rear window defroster. The Dodge 600 weighs about 2680 pounds, the

turbocharged 2.2 is rated at 142 hp, and the automatic transmission has

a gear ratio of 3.02-to-1. I chose as a realistic goal a 14-second elapsed

time and 90 mph in the quarter mile. Before any major power improvments

were undertaken, I thought it wise to inspect the lower end of the engine

and at the same time install a higher volume oil pump. After the oil pump

and pan were in, the cylinder head was pulled, cleaned up and reinstalled

with new head bolts.

To check out the car and establish a baseline, I ran it at the strip until

consistent results were acheived. These first runs were exactly as expected

and comparable to the original Chrysler advertised figures. The slowest

run was a 17.14 at 79.6 mph and the quickest was a 16.85 at 80.8 mph. Not

particularly exciting but certainly promising, as the horsepower-to-weight

calculations showed the engine to be producing at least 127 hp. (Some errors

can be expected in the calculated values, compared with the Chrysler rating

of 142 hp, because the standard tables I used aren't as accurate when working

with front-wheel-drive cars.)

In anyone's modification plan, the first step should be the easiest and

most cost-effective. In the case of "computer controlled" engines, it is

true that changing the chip (or in Chrysler's case, the Logic Module) will

produce a substantial gain in horsepower. Mopar Performance sells a Logic

Module for the '84 turbos that installs in minutes, provides a more aggressive

spark timing curve, a richer fuel mixture and higher rpm engine cutoff,

and allows a boost pressure increase from 7.2 psi to about 10.0. Owners

who install this computer chip will find that 92 octane fuel is not high

enough to prevent detonation. I solved this problem by mixing 100 octane

low lead aviation fuel with unleaded premium. Beware of the likelihood

of poisoning the oxygen sensor and the catalytic converter with large volumes

of this fuel. Drag strip elapsed times showed a great deal of improvement,

with the slowest time of the day being a 16.14 at 83.5 mph and the best

a 15.90 at 94.8 mph. Calculations showed the Logic Module to be worth about

15 hp. Not only was the 600 coupe's performance respectable, it could now

run with automatic transmission-equipped Z28s, Trans Ams and Mustangs.

|

The Logic Module, found under the right kick panel inside all Chrysler

turbocharged cars, is the brains behind all the engine functions. |

After studying some basic turbocharger theory, I decided a reduction of

exhaust backpressure and a "streamlining" of the air intake system would

give some more performance gains. I bought some 2.5 inch diameter 409 series

stainless steel tubing, and a custom exhaust shop bent a new system for

me that used a stainless steel Sonic Turbo muffler and had no provisions

for a catalytic converter. Without the converter, a system like this has

to be considered "strictly off-road," so applicable laws should be checked

before using it on the street.

| Air cleaner cover was polished in area indicated by

pointer. |

|

|

|

Stock exhaust (right) was replaced with a custom-bent system using

2.5 inch stainless steel tubing, a Sonic Turbo muffler and no provisions

for a catalytic converter. |

I removed the turbocharger compressor inlet elbow, the air cleaner hose-to-throttle

body adapter and the air cleaner cover, eliminated all the casting flash

and polished them internally. Installation was completed with a K&N

air filter element. The intake modifications I performed were similar to

what a person would do to an intake manifold on a V8 engine. However, I

had an easier time since most of my components were plastic. A road test

revealed a remarkable difference in driveability, and it was obvious the

drag strip times would correlate. The strip times confirmed this: a slowest

time of 15.75 at 87.71 mph and a fastest of 15.65 at 88.75 mph. Horsepower

calculations showed the better-breathing 2.2 was providing at least 165

hp; that's another 20 on top of the 18 added by the Logic Module and higher

octane fuel. Since my 2.2 turbocharged engine was approximately 30 percent

more powerful now than it was in its stock configuration, I began to get

concerned about driveline breakage. A little research educated me a bit.

The older FWD transaxles had a differential mounting configuration that

was not capable of sustaining wide open throttle, drag strip-style starts.

I also learned that Chrysler had corrected this problem in the '87 and

newer automatic transaxles.

The third step in my quest for a 14-second FWD automatic was the hardest

to complete and the most expensive. I was aware of the transaxle redesign

in the 1987 and newer Chrysler turbo cars, so I limited my search to one

of those. After its aquisition, I had the ring and pinion changed from

the stock 3.02-1 ratio to a lower 3.22-1. The torque converter used was

built to specs provided by a Chrysler torque-converter expert, and I acquired

a flywheel to attach this new 4-bolt converter to my existing 6-bolt crankshaft

flange and 3-bolt converter. (Note '84s used a 6-bolt crank flange and

3-bolt converter; newer vehicles have an 8-bolt crank flange and a 4-bolt

converter.) The transaxles for 1987 and later turbocharged Chrysler cars

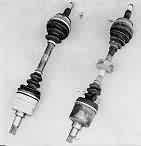

drive through stronger axle shafts, so these too were replaced.

| Installation of the new, larger drive axle (left) led

to a previously impossible condition: wheelspin! |

|

|

New intermediate shaft (top) replaced the original, smaller piece. |

Installation of the new transaxle was a six-hour job that went relatively

smoothly. After completion, a few trips around the block confirmed what

I had hoped for. My Dodge 600 was now capable of wheelspin from a slow

roll- something that was not possible before the transaxle change. Before

my next drag strip test, I installed a 3 inch air duct from below the front

valance to the air box in order to provide an ample supply of cold air.

I again mixed the fuel to obtain sufficient octane. My first run surprised

even me with a 15.31 at 88.9 mph. The transaxle had obviously made a great

improvement in bottom end performance, because now I was fighting wheelspin.

Later in the evening I had back-to-back runs of 15.17 at 90 mph, and it

was obvious 14-second elapsed times were only a quicker start away. Horsepower

was calculated to be about 170, an overall improvement of 43 so far. After

about 4000 miles and 50 passes at the strip, I began to notice a buzzing

noise from the converter area. I pulled the transaxle and had the converter

cut apart, and it's here that the damage was found. I had wiped out the

thrust washer assembly that takes all the load during high stall conditions.

|

Special torque converter was built to specs provided

by a Chrysler torque converter specialist. Two failed thrust washers are

at center. |

|

I settled on a new torque converter sold by Turbo-Action (as well as

Mopar Performance) that has needle bearings instead of the bronze and babbit

thrust washers. It is slightly tighter than the factory unit I had installed

with the heavier duty transaxle. The new converter required a few modifications

before I could install it. The early transaxle that it was designed for

used an oil pump that has a drive gear with two tabs in its inside diameter,

which the converter hub engages. My later-transaxle oil pump has two flats

on its i.d., so I had to have a machine shop mill corresponding flats on

the hub of my new converter. This converter has three mounting bolts, so

the original 3-bolt flywheel was reinstalled. The Top Dead Center mark

was also made more obvious (2.2s are timed through a hole in the bellhousing

by a mark machined on the converter). Back at the strip, it appeared that

the tighter converter was exactly what I needed to kill some of the 2.2s

low end torque. Best time of the day was a 15.05 at a slightly slower 89.0

mph. I still, however, could not get into the 14s. My only hope was to

find more horsepower. My Logic Module already was running the engine with

maximum boost, fuel and timing. Luckily, I stumbled across a rather devious

but very intelligent auto-oriented computer head who fabricated a new chip

for my existing module. This one would allow as high as 14 psi of boost;

however, my stock injectors are only safe up to about 12 psi. I set the

boost at 11.5 via various tuned bleed-off orifices and went back to the

strip. First run success finally arrived with a timeslip that read 14.96

at 90.0 mph. After a couple more runs, I stopped with a best time of 14.77

at 90.7 mph. The last race for me in 1988 was our Second Annual Mopar Day

at Kansas City International Raceway on October 16. The weather was good,

with the temperature at 80 degrees, relative humidity at 35 percent and

the barometer at 29.98. Since the new Logic Module chip would allow temporary

overboost, I opened the exhaust system. (The other modules had only minimal

tolerance for overboost, and opening the exhaust would consistently let

the turbo spin up quicker than the wastegate could control. This generally

cause the overboost condition.) This was going to be a good day to compare

the performance of my '80s FWD musclecar with the '60s and '70s Mopar RWD

musclecars. The initial run was an exciting 14.48 at 93.9 mph. Horsepower

calculated to about 192; the new devious box combined with open exhaust

increased the power another 22 hp, but lowering the boost put it back to

a safer 182. Subsequent runs were all between 14.47 and 14.51. As the day

progressed, it appeared that my injectors were not supplying the fuel,

so I lowered the boost slightly and dialed the car in on a 14.60, and the

mph stabilized at 92.0. I let a very good (and consistent) friend drive

the 600 in the bracket race, and he piloted it to a runner up finish in

the 13.00 to 14.99 class. Who would have thought that an '84 Dodge 600

four-cylinder would be at the strip, much less competing the same class

with just about every other factory Mopar musclecar ever made?

After the 14.40s, I finally was as far as I figured I could get with my

existing non-intercooled 2.2 setup. However, I couldn't stop at 93 or 94

mph. A few more calculations showed 98 mph was in reach, with only 200

hp needed to get there. My injectors would not support the 200 hp attempt,

and without nitrous oxide I knew I was at the end of my road. But luck

would again go my way, as I was able to purchase a complete intercooler

manifold, intercooler and all the associated hardware needed to adapt it

to my vehicle. The first step was to disassemble my old hardware, While

the head was off, I checked and cleaned the valves and installed new valve

seats. I also drilled and tapped the block for the new 11 mm head bolts

that give the much-needed clamping power. The new intake I installed was

a two-piece tuned unit that changed the torque peak to a lower rpm level--just

exactly what my automatic-equipped 600 needed. While it was off the car,

I also matched the two halves of the intake to the gasket, therefore matching

the runners, much like one would match the intake to the heads on a V8.

|

| Intercooler (arrow) was borrowed from an '87 Daytona

and instantly improved ET and mph in the quarter mile. |

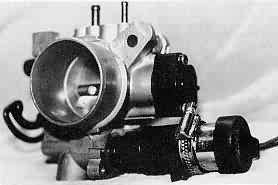

Surprisingly, everything bolted on my 1984 600 K-Body, even though it

was intended for an '87 G-Body (Daytona). I did, however, have a number

of items that needed to be modified and/or removed. Initially the new throttle

body was a big problem. However, my advisor in this new project engineered

an aluminum sleeve that let my old 1984 motor-driven "valve" idle motor

fit onto the new throttle body, which originally used a motor that pushed

a plunger in and out of the orifice in the body. Right after I thought

things were solved with the throttle body-idle motor problem, I realized

the hood would not shut, as the water drain trough sits on top of the new

tuned intake. I left the room as my dad used his metal cutters to trim

off the offending sheetmetal. I guess this is how people feel when they

cut holes in their hoods to clear blowers and carburetors.

My old radiator had two additional parts that the new intercooler radiator

assmebly didn't. One was a hose nipple that was the return for the heater

hose, and the second was a female pipe fitting that accepted the radiator

fan thermostat switch-sensor. I bought a 4 inch long piece of 1.5 inch

diameter pipe and welded on the correct size nipple for the heater hose

and the female pipe fitting to accept the thermostat switch-sensor. I had

to buy an '87 Turbo II Daytona lower radiator hose and use the smaller

diameter section of it on one side of my new 1.25 inch adapter. Then I

cut my old hose and attached it to the other side of the adapter. Software

problems always surface with computerized items, and this project was no

exception. However, my devious but auto-oriented computer head friend corrected

my Logic Module to feed the new high-flowing injectors and allow for the

100 degree of (average) temperature drop air that the intercooler would

provide.

|

| Opening in old idle motor connects to a custom-fabricated

aluminum sleeve. |

After some minor tuning on the throttle body to bleed more air through

the idle motor assembly, I was able to achieve a respectable idle. It's

amazing how much torque this combination yields. I couldn't believe how

responsive the four cylinder really felt. It sort of reminded me of a 340

automatic Dart I once had. After a two-month proving, I was ready for the

strip. I left my exhaust hooked up and the boost set at 10 psi. I ran only

92 octane unleaded Amoco fuel. The very first run was a 14.76 at about

94 mph but with a lot of wheelspin. Before the intercooler, it took 11.5

to 12 psi and good fuel to even touch the 94 mph range. I cranked the boost

up to 12 to 12.5 psi and the times dropped to 14.40 at 96 mph. The final

runs were made with the exhaust opened, and even a Grand National was surprised

with my best time of 14.14 at 98 mph. Later runs would raise the speed

to 99 mph, but ET stayed around 14.20. When I calculated the horsepower,

it worked out to some 200 to 205. What's more, the times and mph reflected

another resounding change--all of this from a car that started out turning

17.14 at 79 mph.

I'm always a bit skeptical when I read an article such as this on performance

modifications. There are always bad things that go hand in hand with the

good, and this project was no different. I'll give a brief synopsis of

the disadvantages I noted. The Logic Modules improve power a great deal,

but very high octane fuel is required. The second special module I ran

the 14s with is not yet commercially available, but there are many fuel

enrichment devices that could possibly achieve the same results. The Chrysler

electronic system adapts to any type of fuel by using a detonation sensor

to control pre-ignition, but the subsequent retardation of total advance

is very noticable in a seat-of-the-pants feel. The new exhaust system is

not any louder than the original one, but the absence of the catalytic

converter makes it illegal for street use. Enough said. I still strongly

feel that 13.90s at 98 mph are possible, but I'm not sure my Michelin 195/70R-14

whitewalls will supply the needed traction. Even in 95 degree weather,

the intercooler allows me to run only 92 octane fuel without detonation

at 12 psi boost, and this provides more than enough torque to roast the

front tires. At the strip, I've been posting about a 65% success rate against

5.0 liter mildly modified Mustangs, and even the semi-stock Grand Nationals

can't consistently beat me. I'd have to say I'm satisfied with the 3 second

decrease (17.14 to 14.14) and 20 mph increase in quarter mile performance.

Even the fuel economy decrease from the stock 27 mpg highway/20 mpg city

to the 21 highway/16.5 city that the car attains now isn't all that major.

I'd like to thank Dr. Prom for the electronics wizardry, Dr. Nosh for

the transmission information and Dr. Bob for the adaptation guidelines.

Without the help of these three, I couldn't have met and exceeded my original

14 second, 90 mph goals. |